Dewalt Oscillating Tool Blades

August 7, 2025 by: Josh McGaffigan

Dewalt Oscillating Tool Blades That DIY Pros Swear By for Precision and Power

Types of Dewalt oscillating tool blades and their specific uses

When it comes to versatility, Dewalt oscillating tool blades are in a league of their own. Whether you’re working on demolition, sanding, or detailed cuts, Dewalt makes sure you’re covered. They offer a wide array of blade types: bi-metal blades for metal, carbide grit blades for tough materials like cement board, and precision wood blades for those crisp, splinter-free cuts. Each type serves a specific role, helping you avoid the dreaded one-size-fits-none approach.

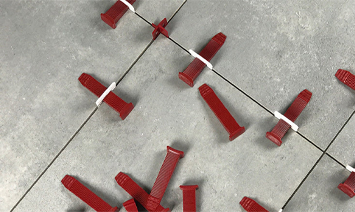

Woodworking? The straight-cut wood blades with wide profiles are perfect for aggressive plunge cuts. Got some plumbing to do? Dewalt’s metal blades are designed to chew through copper pipes and nails without giving up halfway through. Tiling? The grout-removal carbide blades are aggressive yet controlled, giving you clean lines without busting through tile edges.

Knowing which blade to grab for which task can make or break your workflow. Misusing a metal-cutting blade on wood won’t just waste time—it’ll wear out your tools and lead to jagged results. Dewalt takes the guesswork out with color-coded packages and clear labeling so you can pick the right one in seconds.

Blade material differences and how they impact performance

Not all Dewalt oscillating tool blades are created equal—blade material matters more than you think. High-carbon steel (HCS) blades, for instance, are great for soft materials like wood and plastic. They’re flexible, affordable, and easy to control, but they’ll wear out quickly on harder surfaces.

For tougher materials, Dewalt offers bi-metal (BiM) blades, which combine the flexibility of HCS with the hardness of high-speed steel. These are the sweet spot for metal, hardwood, and more demanding tasks. They last longer and handle abuse like champs. Then there are carbide-tipped blades, the top-tier options for extreme durability. If you’re cutting masonry or hardened screws, carbide is the way to go.

Choosing the wrong material means burning through blades faster—and potentially overheating your oscillating tool. Stick to blades built for the job, and you’ll not only save money but also boost performance. Dewalt’s packaging helps here too, clearly outlining blade durability, application, and expected lifespan.

How to choose the right Dewalt blade for your project

You wouldn’t wear dress shoes to a hiking trail, right? Same logic applies when picking your Dewalt oscillating tool blades. Start by identifying your material—wood, metal, drywall, grout, or plastic. Dewalt usually includes this directly on the blade or the packaging, so you won’t need to guess.

Next, think about the type of cut. Are you making plunge cuts into a tight space? A narrow, straight blade will give you control. Need to scrape adhesive or remove old caulk? A flexible scraper blade is what you want. For sanding, Dewalt also makes triangular sanding attachments that snap right into your oscillating tool like a dream.

Lastly, compatibility is key. Dewalt blades are designed with a universal fit system, which works with most major oscillating tool brands. Still, double-check the connector type if you’re using a third-party tool—especially older models.

Understanding blade tooth configurations for cleaner cuts

Tooth configuration may sound like a minor detail, but it plays a huge role in how clean, fast, or aggressive your cut ends up. Dewalt oscillating tool blades come in a range of configurations, from fine-tooth to large gullet designs. The finer the tooth, the smoother the cut—but it also means slower progress.

For softwoods and plastics, go with a wide-tooth blade—it’s faster and less prone to clogging. But if you’re doing finish work or trimming exposed edges, fine-tooth blades deliver the surgical precision you need. Metal blades, on the other hand, usually feature a wave or Japanese tooth pattern to distribute heat and prevent the blade from bogging down.

Keep in mind, higher tooth-per-inch (TPI) blades wear slower but cut slower too. Lower TPI blades make quicker work of soft materials but tend to dull faster. Dewalt designs each blade with this tradeoff in mind, offering the ideal balance of speed and finish.

Comparing Dewalt oscillating tool blades to other leading brands

Let’s be real—Dewalt isn’t the only game in town. Brands like Milwaukee, Bosch, and Dremel also offer quality oscillating blades. But Dewalt consistently gets praise for one thing: balance. Their blades last long without being outrageously priced, and they cut clean without requiring a ton of pressure.

Compared to Milwaukee, Dewalt blades are more affordable and come in larger variety packs. Bosch often leads in specialized blades like grout removers, but Dewalt holds its ground by delivering universal compatibility and better value. Dremel, on the other hand, leans toward precision tools and tends to be more niche-focused.

All things considered, Dewalt is the all-rounder in the blade market. You get consistent quality, a blade for nearly every application, and compatibility that won’t leave you frustrated halfway through a job. That’s why you’ll see their yellow and black blades in both pro shops and weekend DIY kits alike.

Tips for extending the lifespan of your Dewalt blades

Let’s face it—oscillating blades aren’t cheap. But with a little care, your Dewalt oscillating tool blades can last significantly longer. First off, let the tool do the work. Don’t force cuts. Excess pressure leads to overheating, which degrades both the blade and the motor.

Second, match the blade to the material. Using a wood blade on metal will grind down the teeth in seconds. If you’re cutting mixed materials—say, nails embedded in wood—opt for a bi-metal or carbide blade to avoid surprise stalls.

Lastly, clean your blades. Resin buildup from wood or adhesive can dull edges and increase friction. A quick soak in mineral spirits and a soft brush scrub can breathe new life into a blade you were about to toss. Bonus tip? Rotate your blades between projects to give them a breather and extend their lifespan.

Using Dewalt blades for wood, metal, grout, and more

Versatility is where Dewalt really shines. You can tackle a wide range of materials without swapping tools—just switch the blade. For wood, Dewalt’s straight-cut and semi-circular wood blades glide through studs, trim, and plywood effortlessly. Need to cut flush against a wall? Their offset wood blades make that a breeze.

Working with metal? Dewalt’s bi-metal blades slice through nails, conduit, and even angle brackets without chattering or bending. For bathroom projects, you’ll appreciate the carbide grit blades—they grind through grout and cement board cleanly, without cracking surrounding tiles.

Plastic and PVC also cut like butter using Dewalt’s HCS blades. The trick is low vibration and consistent torque, both of which are delivered through Dewalt’s finely tuned balance. Whether you’re a remodeler or weekend warrior, Dewalt blades turn one tool into a jobsite Swiss Army knife.

Must-have Dewalt blade sets for professionals and DIYers

You could buy blades one at a time—but trust me, blade sets are the smarter play. Dewalt offers a range of kits tailored for everything from general contractors to hobbyists. The 10-piece Tough Case set, for example, includes wood, metal, and specialty blades all neatly packed in a stackable organizer. Perfect for keeping your workspace tight and your blades protected.

For heavy users, the 15-piece Max Fit blade set offers extended-life metal and wood blades, as well as a sanding pad. It’s basically the greatest hits of Dewalt oscillating tool blades, ideal for those who need to jump between tasks without rummaging through a toolbox.

Even if you only use oscillating tools occasionally, Dewalt’s starter sets offer great value and introduce you to the most-used blades—so you know what to restock when you burn through your favorites.

Safety tips when using Dewalt oscillating tool blades

Using oscillating tools might feel intuitive, but don’t let that fool you into skipping safety. Start by wearing eye protection—debris can fly fast and sharp, especially with metal cuts. For longer projects, ear protection is smart too. These tools get noisy in tight spaces.

Never touch a blade immediately after cutting—Dewalt’s metal blades in particular get scorchingly hot. Give it a few minutes or use pliers if you’re in a hurry. Also, always secure your material before you cut. A wobbly board or loose pipe can cause the blade to skip and damage the material—or worse, your hand.

Finally, inspect your blades before and after use. Cracks, chips, or excessive wear can lead to poor performance and safety hazards. Replace dull or damaged blades immediately. Dewalt makes safety a priority in its designs, but it’s still up to you to use them responsibly.

Where to buy genuine Dewalt oscillating blades at the best price

With so many knockoffs out there, it’s critical to buy Dewalt oscillating tool blades from a trusted retailer. Big-box stores like Home Depot and Lowe’s usually carry full Dewalt selections. Online marketplaces like Amazon are convenient but be cautious—only buy from listings marked “Ships from and sold by Amazon” or directly from Dewalt’s authorized store.

If you’re a tradesperson or contractor, Dewalt’s Tough System and Max Fit kits often go on sale at tool supply chains like Acme Tools or Tool Nut. Signing up for email lists can get you early access to promotions and bundles.

Price aside, make sure you’re getting the real deal. Fake blades often don’t meet safety standards and can warp or break during use. Look for Dewalt’s authentic packaging, model numbers, and universal fit labels to stay on the safe side.

Conclusion

Dewalt oscillating tool blades aren’t just accessories—they’re workhorses that define the quality and efficiency of every project you tackle. From cutting trim and grinding grout to sanding tight corners and slicing through nails, these blades make your multi-tool feel like a precision instrument. We’ve covered their blade types, materials, use cases, and safety tips—all so you can choose and use them with confidence.